-

Brief history of roll development

[2020-07-03]With the development of metallurgical technology and the evolution of rolling equipment, the variety and manufacturing technology of roll are developing. In the Middle Ages, low strength gray cast iron rolls were used for rolling soft Non-ferrous metal. In the middle of the 18th century, England mastered the production technique of cold-setting cast iron rolls for rolling steel plates. The improve

-

Performance requirements for rolls

[2020-07-03]The work roll of small 20-high mill only weighs about 100g, but the weight of the back-up roll of wide and heavy plate mill has exceeded 200t. According to the basic strength requirement of the rolling mill, the main material of safety bearing is selected, such as cast iron, cast steel or forged steel, etc. . Folding hardness and high speed finishing roll, rolling the final product to have

-

What should roll grinder work notice

[2020-07-03]1. Pay Close attention to the contact between the grinding wheel and the surface of the workpiece. When the surface of the workpiece is just in contact with the grinding wheel, continuous hissing sound can be heard. The water traces on the surface of the workpiece can be carried away by the rotating grinding wheel. At the same time, a faint spark can be seen. Cooling liquid should choose a slightl

-

What are the components of a roller grinder

[2020-07-03]The roller grinder is composed of bed, head frame, tail frame, bracket, Longitudinal and transverse dragging board,grinding head, measuring frame and electrical numerical control system. The workpiece is supported by the head frame, tail frame and bracket, and is driven to rotate by the head frame. According to the mathematical model of roll surface Generatrix, the CNC system controls th

-

The roll produces elastic flattening for the minimum plate thickness

[2020-07-03]The minimum thickness of a plate that can be rolled when the roll is elastically flattened. When rolling certain products on a certain rolling mill, it is more and more difficult to press down with the plate and strip thinning gradually. When the Strip is thin to a certain limit, no matter how the screw is screwed or the hydraulic pressure is increased, no matter how many passes are repeatedly rol

-

Stainless steel pipe can form rollers

[2020-07-03]In the production of stainless steel tubes (titanium tubes) from stainless steel strips, a process called cold welding is sometimes employed. But cold welding can damage the surface of stainless steel tube (titanium tube) . In addition, the relative tangent velocity between the Tube and the roll is the main reason for the friction between the tube and the roll. Due to the influence of cold welding

-

The chemical composition of the roller has been improved

[2020-07-03]Prior to October 18,2009, the control of chemical composition in front of the furnace in the foundry workshop was completed once by hand, and the process control was based on experience. Since the introduction of spectrometer on October 18,2009, chemical composition adjustment in front of the furnace is divided into two tests: initial sample and duplicate sample, which increases the controllabilit

-

Effective method of improving roll

[2020-07-03]High-speed steel roll has the advantages of long service life, smooth material surface and even thickness. At present, Centrifugal casting is widely used in industry to produce high-speed Steel Roll Rings, which is simple in process and low in cost. However, due to the high content of CR, V, W, Mo and other alloy elements in high-speed steel materials for rolls, therefore, under the action of Cent

|

|

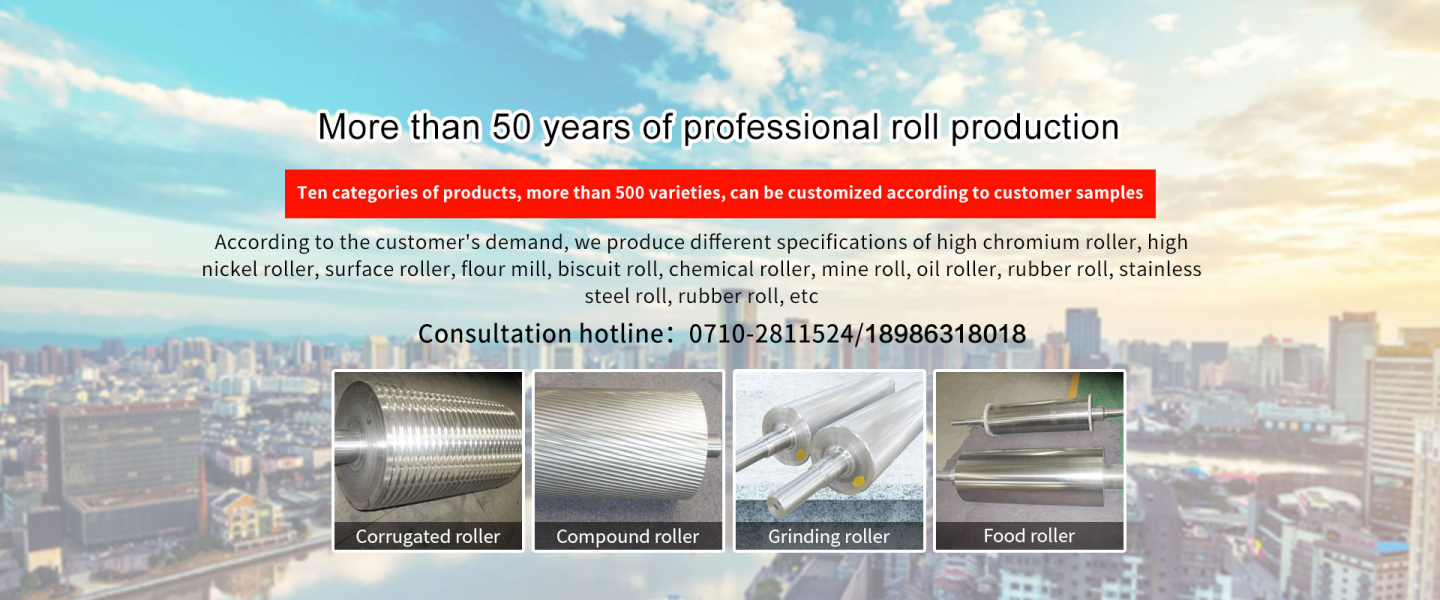

Product display Roll display |

Contact us Contact: Mr. Fang Tel: 18986318018 Address: South of Diamond Avenue, Xiangzhou District, Xiangyang |

About us About us Honor and qualification |