The minimum thickness of a plate that can be rolled when the roll is elastically flattened. When rolling certain products on a certain rolling mill, it is more and more difficult to press down with the plate and strip thinning gradually. When the Strip is thin to a certain limit, no matter how the screw is screwed or the hydraulic pressure is increased, no matter how many passes are repeatedly rolled, it is impossible to thin the product because of the

elastic flattening of the rollers. This limiting thickness is called the minimum allowable thickness. During rolling, the work piece interacts with the roll, and the work piece deforms plastically under the action of the roll, and the work piece deforms elastically under the reaction of the mill and the roll. Of course, the workpiece is accompanied by a small elastic deformation, through the roller elastic deformation after a small amount of recovery, increasing the thickness of the workpiece. As shown in the figure, the rolled piece of thickness h is rolled down h, but the rolled piece is reduced h 1 due to elastic deformation of the roll, and the rolled piece is reduced h 2 due to the recovery of elastic deformation of the rolled piece. As a result, the actual reduction H . Stong M. D. Stone, HMS Roberts W. L. Roberts, Ford-Alexandre h. Ford-j. M. Al-exander and others have made theoretical derivation of the minimum rolling thickness formula.

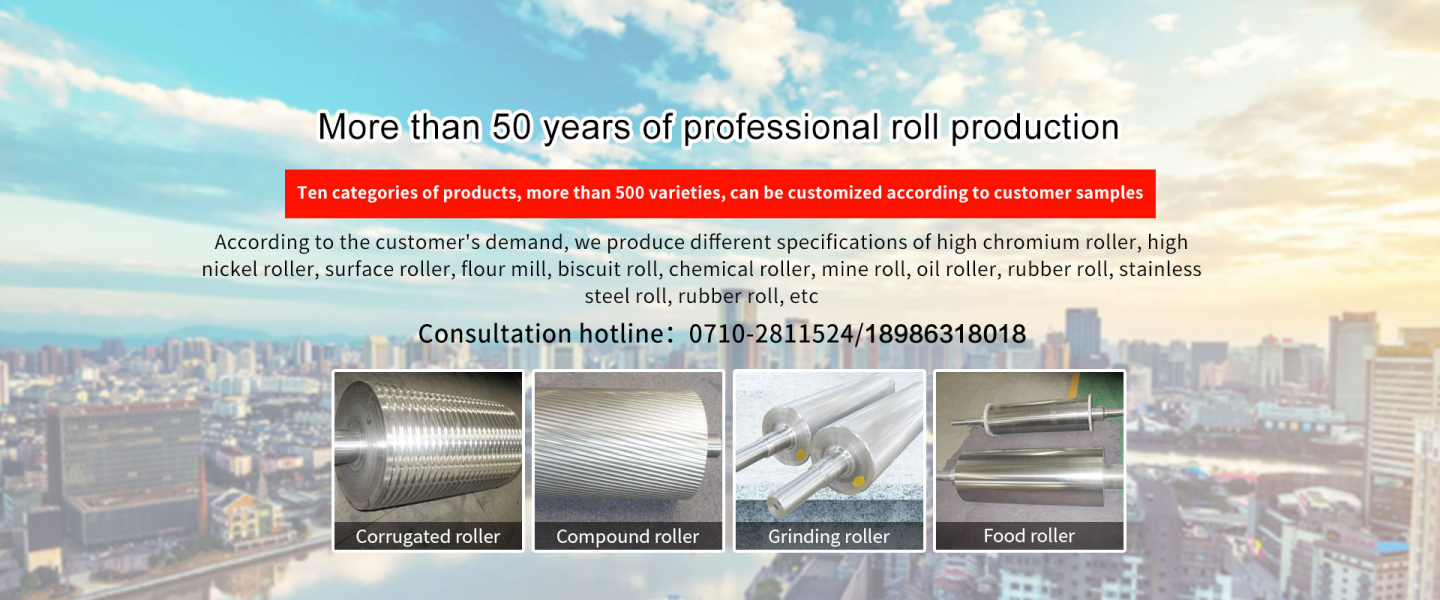

According to the formula deduced by Stong, the minimum thickness Hmin 3.58 D K / d is the diameter of work roll, the Coefficient of friction, the resistance to metal plane deformation and the Mechanical Modulus of Elasticity. In order to roll thin strip, it is necessary to reduce the diameter of work roll, adopt high efficient technology lubricant to lubricate the plastic process, reduce the deformation resistance of metal, increase the elastic modulus of roll, and effectively reduce the elastic flattening of roll. Tungsten carbide rolls up to 10 mm in diameter are used in modern 20-high mills to roll extremely thin strip steel up to 0.001 mm in thickness. In engineering, the ratio between the diameter of work roll and the thickness of finished strip can be determined according to the following formula. When increasing the number of intermediate annealing and rolling passes, D ≤2000h, the asynchronous rolling technology can break through the limitation of the minimum allowable thickness, the principle is different from the general rolling theory. High speed steel roll, used roll, roll repair